Plug & Play Machine Monitoring

An Award-winning machine monitoring platform that enables factories to achieve manufacturing excellence.

Increase Machine productivity

Use data to enable continuous improvement

TIME TO DITCH THE CLIPBOARD

Manual data capture is inaccurate, time-consuming and typically outdated by the time it is acted upon.

FourJaw automatically captures your machine data in real time, enabling you to understand where inefficiencies are in your production line.

The accurate data insight FourJaw provides enables you to focus your attention to remove inefficiencies where it matters most.

With FourJaw, you know with confidence whether today was a good day or a bad day on the factory floor.

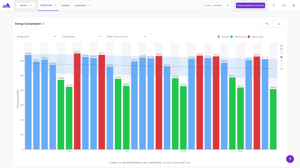

Reduce Wasted Energy Consumption

WHY FOURJAW IS DIFFERENT

| Traditional Solutions | FourJaw | |

|

Plug & Play Installation |

||

|

Monthly Subscription |

||

|

No Large Upfront Costs |

||

|

ROI in Weeks, Not Months |

||

|

Works on Any Machine, Regardless of Age or Brand |

||

|

Regular Security & Feature Updates Included |

||

|

Productivity & Energy Monitoring features |

Plug & Play Installation

Monthly Subscription

No Large Upfront Costs

ROI in Weeks, Not Months

Works on Any Machine, Regardless of Age or Brand

Regular Security & Feature Updates Included

Productivity & Energy Monitoring features

RECOGNISED BY INDUSTRY:

Get a Free Demo of FourJaw's Manufacturing Software

FourJaw helps you maximise productivity, optimise team collaboration, and make data-driven choices, all on one easy-to-use platform. Request a FREE one-to-one demo to unlock your factory's full potential today.

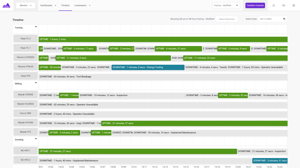

Measure

- Machine Utilisation

- Energy Monitoring

- OEE Monitoring

Analyse

- Downtime Reasons

- Job Tracking

- Custom Reports

React

- Live Data

- Chat Messenger

- Automatic Alerts

Frequently Asked Questions

FourJaw's machine monitoring solution is designed for use on all types of manufacturing equipment.

Generally, if it has an electrical current, FourJaw can tell you how productive it is (and how much energy it uses).

Absolutely. We've tailored our machine monitoring system to ensure it's usable by manufacturers across the board, which includes ensuring compatibility with machines of every age, make, or model. This means even machinery that's decades old can be upgraded to a "smart machine," enabling you to gain insights into the productivity of your equipment.

Where conventional systems might read any spindle movement as "productivity", FourJaw accurately detects genuine, money-making productivity. For example, FourJaw can detect when a CNC machine is cutting metal, by observing the rise in current usage during actual work.

This not only provides a more accurate measure of machine efficiency but also ensures consistency in data across all machines, facilitating better decision-making across your factory.

FourJaw captures downtime data through a combination of its MachineLink hardware and tablets mounted on the machines.

When a MachineLink detects downtime, it automatically prompts the operator via the tablet to select the reason for this downtime from a predefined list.

This process is quick and non-disruptive, designed to minimise interruption to the operator's workflow.

By simplifying the input method to just a few taps, FourJaw ensures that accurate downtime reasons are recorded with minimal effort, enabling a comprehensive analysis of machine productivity and downtime causes without impeding your operators.

Yes. Unlike traditional machine monitoring solutions, we designed our machine monitoring platform to be accessible, not only did we make it easy to install (minimising disruption to your factory floor) but we also made it affordable.

We offer monthly payment plans and you can install it yourself, so there are no high upfront installation costs often associated with traditional machine monitoring solutions. Find out more about the pricing plans we offer here.

- Boost Efficiency: Pinpoint and address bottlenecks and areas of inefficiency within your manufacturing processes, streamlining operations.

- Reduce Unplanned Downtime: With our downtime monitoring feature, you can identify all your reasons for unplanned downtime, allowing for targeted interventions to prevent future occurrences.

- Informed Decision-Making: FourJaw provides deep insights and data, empowering you to make well-informed decisions regarding staffing, machinery investments, and more.

- Cost Reduction: FourJaw's real-time monitoring capability enables early detection of potential issues, helping prevent costly downtime, failures, and other expenses.

- Customer Satisfaction: By optimising your manufacturing processes for better efficiency and quality, you'll deliver products that meet or exceed customer expectations, enhancing satisfaction and loyalty.